CIMCO Offers CNC Editing, DNC and Probing Solutions

Make your shop smarter with sophisticated, real-time data collection, communication and CNC editing tools.

Adding CIMCO products to your shop floor will not only give you great tools to get the job done, but also a powerful and integrated platform for editing, designing, visualizing, managing and communicating CNC programs and related content.

CIMCO PROBING FOR MASTERCAM

Program your machining probe as easily as programming toolpaths with this fully-integrated probing add-on for Mastercam by CIMCO.

KEY FEATURES

CIMCO Probing includes a wide range of Probe Cycles to handle most measurement needs. Cycles can be customized through user-defined parameters with assisting drawings that make it easy to see what each parameter controls in the cycle. For convenience, CIMCO Probing can intelligently fill in parameter values based on stock model geometry.

Surface Probing makes it easy to select surface points and surface normals on curved geometry. For any point chosen on the model, a measuring cycle is generated and the result of the measurements is compared with the 3D model.

CIMCO Probing works seamlessly inside Mastercam and includes its own dedicated tab in the Ribbon bar with icons for adding Cycle or Surface Probing. Probing options are shown in the Manager Panel and once a cycle is added, it is stored in Mastercam’s Toolpath Manager where it can be repeatedly adjusted as needed.

All probe tool movements can be fully visualized and verified using Mastercam’s Backplot, Verify and Machine Simulation. In addition to being convenient, this also provides confidence that your probe tool remains undamaged during machining. Probe tool collisions can be detected and resolved before the program is machined.

Want to learn more about Cimco Probing for Mastercam? Click here to read the Product Spotlight blog!

Want to learn more about Cimco Probing for Mastercam? Click here to read the Product Spotlight blog!

CIMCO SCHEDULER

CIMCO Scheduler is the production scheduling and order tracking solution that helps customers increase the accuracy of delivery dates, identify untapped production capacity, and allows for planning of preventative maintenance.

CIMCO Scheduler provides a central planning board that is driven by real-time data from the shop floor.

Using a specialized mobile interface, machine Operators can provide status updates about orders and machines, which is then instantly reflected in the main planning software and digital signage such as Live Screens and Dashboards.

KEY FEATURES

Timeline-based overview of machines, orders, and dependencies over several weeks. Each machine has its own row with machine status, orders and shifts. Dependencies are shown as lines between orders.

Real-time overview of order and machine status. Orders have indicators and progress bars to show the status of operation, material availability, and delivery. Information can be directed to TV screens for open space monitoring and digital signage.

View the available production capacity for all your machines over weeks and months. Each day is colored to indicate available capacity.

Auto-schedule orders by either placing new orders after the last one scheduled or by placing them further ahead where there is available capacity. Start and end dates can be simulated before scheduling for production.

Modify or delete orders directly from the Timeline or drag-and-drop orders between machines. The consequences of a change are presented for approval before an order, and any affected orders, are automatically rescheduled.

Update order and machine status directly from the shop floor with the Operator interface. Display key order data, start/stop orders, set machine status, or enter reasons for downtime.

Schedule Planned Maintenance similar to orders. If the system is notified that a machine is down, Unplanned Maintenance is auto-inserted in the Timeline and the remaining part of an order, and subsequent orders, are pushed back.

Create custom reports from your order data with the template-based reporting system. Reports can be printed or exported, and templates can be customized with the desired information, layout and style.

Auto-import orders from an external system such as an ERP system (using XML formatted data). Use the automatic scheduling feature to quickly simulate and schedule imported orders.

CIMCO EDIT

The CNC Editor of choice for CNC Programmers around the world who demand a reliable, cost-effective and professional editing tool. Cimco Edit is included with the purchase of Mastercam.

KEY FEATURES

It has no program size limitations and includes CNC code specific options such as line numbering / renumbering, character handling and XYZ range finder. It also features math functions.

CIMCO Edit includes built-in cycles and macros for the most common operations, such as program start, program stop and tool change. You can also record or create custom cycles and macros for the operations most common to your own specific setups and applications.

The 3D Mill / 2D Lathe backplotter handles your 3-axis Mill and 2-axis lathe CNC programs with step and continuous forward and reverse plotting.

CIMCO Edit features a fast and fully configurable side-by-side file compare, allowing the user to quickly identify CNC program changes.

CIMCO DNC MAX

The latest version in a long line of proven DNC solutions. An advanced DNC server with online feed/speed adjustment, remote administration and much more.

KEY FEATURES

In addition to standard Fanuc/Haas style controls DNC-Max includes comprehensive support for Heidenhain, Mazak, Fagor, and many others.

The DNC-Max Client is the PC interface of DNC-Max and allows users to manage local or remote file transfers, monitor machine ports, and perform remote network configuration and administration of multiple servers – from a single point.

The DNC-Max Server is the core component of DNC-Max and handles all communication activities and calculations. It can be run as an application or as a service in the background as required.

The advanced remote control features of DNC-Max allow operators to initiate program transfers directly from the CNC control or from a mobile device using the DNC-Max Web Client.

In addition to the stand-alone PC Client, the full DNC-Client is also available as an add-on for CIMCO Edit providing a seamlessly integrated application interface.

The DNC-Max Web Client is a modern, browser-based application that works on mobile, tablet, desktop and TV. It supports local/remote file transfers, file preview, transfer queue, port organization and much more.

Want to learn more about Cimco DNC-Max? Click here to read the Product Spotlight blog!

Want to learn more about Cimco DNC-Max? Click here to read the Product Spotlight blog!

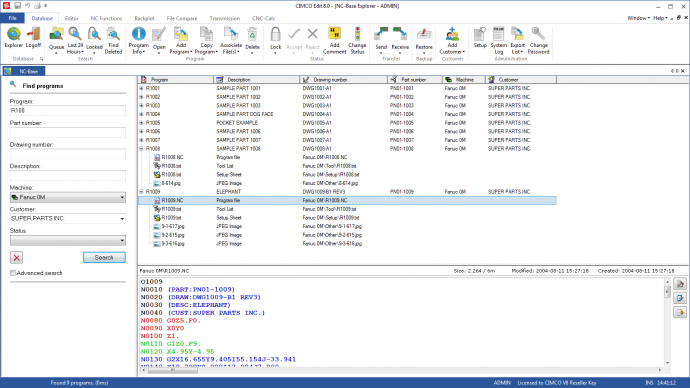

CIMCO NC Base

Serves as an extension to CIMCO Edit and DNC-Max and provides CNC programmers with a powerful, flexible and effective tool for CNC program management.

KEY FEATURES

NC-Base is the CNC program management tool that allows you to organize and manage your CNC programs and related production documents most effectively through the use of a reliable and fast SQL relational database.

With NC-Base CNC programmers and production staff can assemble virtual folders containing all the necessary data used by machinists, operators, quality staff, and others who are responsible for finished parts.

Setup sheets, tool lists, images, and other vital information may be accessed from PCs running the NC-Base Client or printed out for manual distribution.

CNC operators can access and update the database directly from the CNC control, or any PC on the shop floor.

CIMCO MDC-Max

Automatically collect manufacturing data from machines and personnel in real-time to identify causes of production loss, potential areas of improvement and real-time monitor your shop floor for continuous improvement

SCALABLE ARCHITECTURE / MULTIPLE PLANT SUPPORT

AUTOMATIC & MANUAL DATA COLLECTION

REAL-TIME MONITORING / DIGITAL SIGNAGE

NOTIFICATIONS

DOWNTIME TRACKING/OPERATOR FEEDBACK

REPORTING / KPI / OEE

SECURITY

NETWORK CONNECTIONS

INTEGRATES WITH EXTERNAL SYSTEMS

Want to learn more about Cimco MDC-Max? Click here to read the Product Spotlight blog!

Want to learn more about Cimco MDC-Max? Click here to read the Product Spotlight blog!

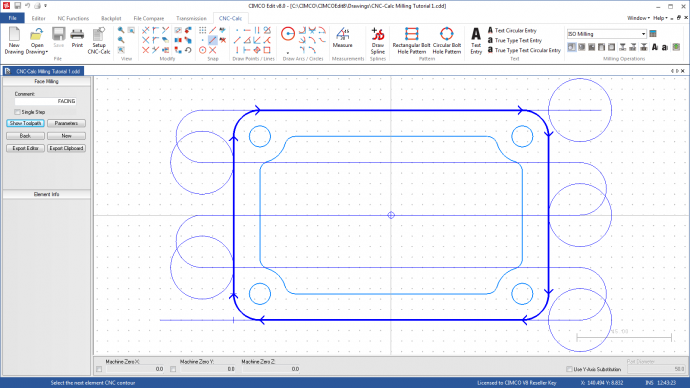

CIMCO CNC Calc

A basic CAD/CAM for the shop floor that works inside CIMCO Edit. This add-on is a fast and effective solution for solving problems with complex 2D geometry.

KEY FEATURES

Designed for ease-of-use that enables the user to draw contours fast and easily

Includes functions for trimming, snapping, rounding corners and generating bolt hole patterns

From DXF files generate toolpaths for lathe and mills, such as ISO, Fanuc and Heidenhain controllers.

CIMCO CNC-Calc performs geometric calculations and toolpath creation in seconds

NC-Assistant, Cycles/Macros, file-comparer, graphical backplotter and more

CIMCO MDM

Manage, transfer and access CNC programs, setup sheets, tool lists, pictures and other essential information directly on the shop floor.

KEY FEATURES

CIMCO MDM is a client/server based system consisting of the MDM Server, MDM Client, and the MDM Web Client. The MDM Server is the core component which handles a fast SQL database and stores the physical files. The MDM Client and Web Client provide intuitive user interfaces for managing documents on the MDM Server. In a small setup the server and client can run on the same PC.

Machines on your network can also connect to the MDM Server and access dedicated machine directories. This provides a number of advantages such as sending and receiving files directly from the machine control.

CIMCO MDM integrates with all your existing applications and has special support for exchanging and managing tool information, NC programs, and previews with CAM software from different vendors. In the MDM Client, launch buttons can be added for your vital applications, and any document type can be set to open in a specific application. Further, document templates can be created for any application and even be configured for specific machine models in your setup for a faster workflow.

Controlling who can access and modify information is a critical component in any information management system. CIMCO MDM provides a highly flexible and secure User Management and Permissions system that enables an administrator to specify the level of access for each user and group, such as who can view, modify, approve, or delete certain documents. The administrator also manages who can backup/restore, send/receive, or add documents and to which groups of machines the authorization applies.

The MDM Web Client enables users to manage documents on the MDM Server from a mobile device such as a smartphone or tablet. Documents can be previewed, modified, and sent to machines – and you can even use the camera of the mobile device to take pictures of your machine setup and store them for future reference. This allows for a more efficient workflow where both CNC programmers and machinists have access to all of their necessary data at a glance.

CIMCO MDM comes with options for automating workflow processes based on document status changes. This enables MDM to e.g. lock or unlock NC files, set a transfer limit, send an email notifications, or request a comment when a certain status-change occurs. Status types and associated actions to be performed can be fully customized for your specific workflow and requirements.

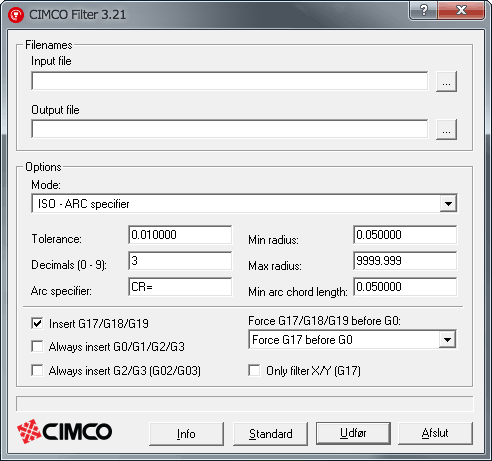

CIMCO Filter

Drastically reduces machining time by converting multiple linear moves into arc moves, creating a much smoother toolpath.

Key Features:

- Improves efficiency

CIMCO Filter improves the efficiency of your old controls, and allows you to fully utilize the 3D arcs and NURBS options on newer controls. - Replacement of linear moves

CIMCO Filter replaces the linear movements (G1 in ISO code) output from the CAM system with arc moves (G2/G3 in ISO code).

- Match CNC control and accuracy

It is possible to set tolerance, arc type, number of decimals and minimum and maximum arc radii to match the CNC control and the desired accuracy.

- ISO, Heidenhain and CL-data formats

CIMCO Filter reads NC-programs in ISO and Heidenhain format and CL-data such as APT files from leading CAD/CAM manufacturers.

- Reduction limits

The machining strategy applied will affect the possible reduction; if there are no moves restricted to one of the three main planes (G17, G18 and G19), no reduction will occur. - Stand-alone or Powercut

CIMCO Filter is used as a stand-alone program, however, it can be purchased as part of the Powercut software.

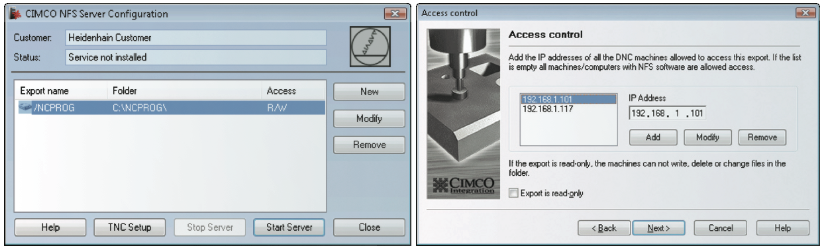

CIMCO NFS/FTP Server

DNC Networking using standard Ethernet connections with NFS or FTP. Large NC programs are transferred from the PC to the CNC controller in seconds.

Key Features:

- Transfer NC programs

Transfer large NC programs in seconds rather than minutes - Multiple exports

It is even possible to export the same folder with different export names and access rights for different machines. - Networking with NFS and CNC machines

The CIMCO NFS Server enables CNC Machines to access the files in a shared folder – called an export – on a server, using a standard network. - Security

CIMCO NFS Server provides a user configurable Access Control List. Only machines whose IP addresses are specified in the Access Control List of an export are allowed access to that export. - Configuring the NFS server

On Windows computers, the server runs as a service, and the NFS Server can be set to start each time the computer does and even is compatible with legacy Windows 95/88 operating systems.