Mill-Turn

Mill-Turn

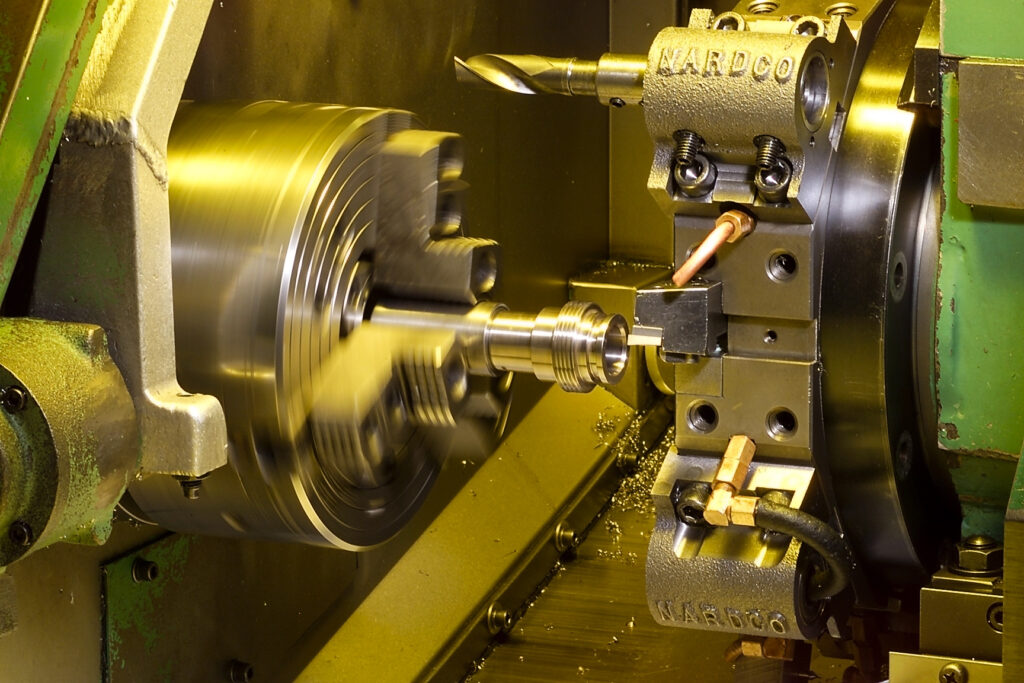

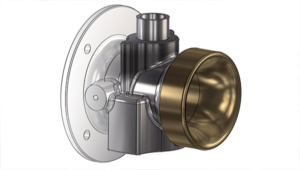

Mastercam Mill-Turn programming streamlines high-power multistream machine centers for increased performance and safety. These multitasking CNC machines reduce multiple setups, manual part handling, redundant fixturing, and idle time for improved productivity in manufacturing.

Using Mastercam’s proven milling and lathe toolpaths, this software simplifies the programming process for mill-turn machines with job setups keyed to the exact machine in your shop.

- Optimization, synchronization, and visualization in a single platform.

- Automation to easily manage complex operations between multiple machine data streams.

- Efficient milling, turning, and drilling operations with fewer setups at high speed.

- Program simple lathes in addition to complex machines.

This lathe mill combination programming software provides a set of routines to program complex parts and test your cutting strategies in a single environment—before your stock is on your multitasking machine. You can use Mill-Turn to machine parts without fear of costly collisions or machine damage.

- Automated job setup

- Intelligent, stock-aware toolpaths

- Powerful Gantt- or Tree-style synchronization

- Intuitive part handling tools specific to your machine

- Full machine simulation with accurate visual feedback

- Powerful Multiaxis cutting

Features

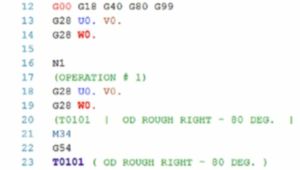

Mastercam Code Expert

Optimize machine movement and synchronization between turrets and spindles with this state-of-the art interface to generate accurate and efficient code.

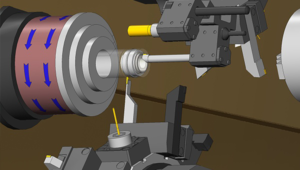

Machine Simulation

Detect collisions between your stock, tool, and machine components before sending code to your machine tool. Machine Simulation is a safe way to prove out 3-axis, 4-axis, or 5-axis toolpaths to make clean, efficient, and accurate programs.

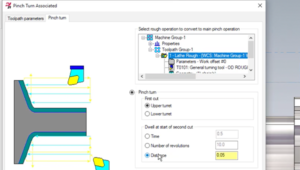

Flexibility

Mastercam Mill-Turn allows you to have a complete post, additional tools made for those machines like pinch and balanced turning, and ease of use for twin spindle, twin turret, and B-axis head machines.

CAD for CAM

A full design package based on a machinists needs including wireframe, surfaces, and solids design; open most CAD file in Mastercam to access modeling and prep tools for CAM programmers to get parts on and off machines quickly.

Partner Benefits

As a result of our partnership with great companies like Sandvik Coromant®, Mastercam Mill-Turn users get the benefits of industry-leading technology like PrimeTurning™ automated toolpath strategies and CoroTurn® tools.

Advanced Technology

Mastercam’s proven toolpaths, intuitive part handling, automated job setup, 3D tooling support, customized milling tools optimized for mill-turn machining, deburring, support for 2- through 5-axis toolpaths, multiturret, multispindle, and more—all managed in a single machine environment.

Want to learn more about Mastercam Mill-Turn? Click here to read the Product Spotlight blog!

Want to learn more about Mastercam Mill-Turn? Click here to read the Product Spotlight blog!