Verisurf / Master3DGage Technical Support Overview

It is our goal to consistently provide the highest level of service and support to each of our valued customers. By following our Support Steps below, you can be assured that your issue will be resolved as quickly and correctly as possible, and will continue to help us reduce response time for technical support issues.

DOCUMENTATION

Verisurf is two pieces of software working together. You will likely find the Mastercam Installation Guide, Transition Guide (if migrating from an earlier version) and the Getting Started Guide for the current version helpful for the first steps of installation and familiarization of your Verisurf system. Visit Verisurf for up to date files and download instructions.

VERISURF BUILT-IN HELP

Verisurf has a built-in Help System that is a great resource. Each operations tab has a linked help function and a reference guide which are the question mark and book symbols. All the reference guides can be accessed from the Verisurf drop down at the top under “user manuals.”

EMAIL SUPPORT

You can send .mcam files to support@mcamnw.com. Make sure that your e-mail explains the problem completely, includes your SIM #, name, company name and the version of Verisurf that you are running. If your email is in regards to an existing customer service case, please be sure to include the HQ# in the subject line to expedite your case.

PHONE SUPPORT

Call us at (503) 653-5332, from 8am to 5pm PST Monday through Friday. Support calls are answered in the order received. If no one is available for immediate assistance you will be forwarded to the tech support voicemail. If your call is related to an existing technical service case, please be sure to include the HQ Number in the voicemail.

PLEASE NOTE

MCAM Northwest has implemented the following Verisurf support program:

Note: Verisurf System Down Errors take precedence over other support. If you are in need of urgent assistance (i.e., Verisurf system is down), please let the receptionist know in your initial call.

2024– Full Support / Updatable / Includes Maintenance Customers / Includes Off-Maintenance Customers

2023– Full Support / Updatable / Includes Maintenance Customers / Includes Off-Maintenance Customers who are 120 Days from current version release date.

2022– Limited Support* / Updatable / Media Replacements Available

2021– Limited Support* / Updatable / Media Replacements Available

2020– Limited Support* / Updatable / Media Replacements Available

2019– Limited Support* / Updatable / Media Replacements Available

2018 – Not Supported / Updatable / No Media Replacement

2017 and Older- Not Supported / Not Updatable** / No Media Replacement

*Support is limited to installation support and HASP setup questions and response time is determined by availability.

**Special offers may be available. Contact us for details.

Thank you in advance for understanding how our program works. This program will continue to help us achieve an efficient and timely return for technical support responses.

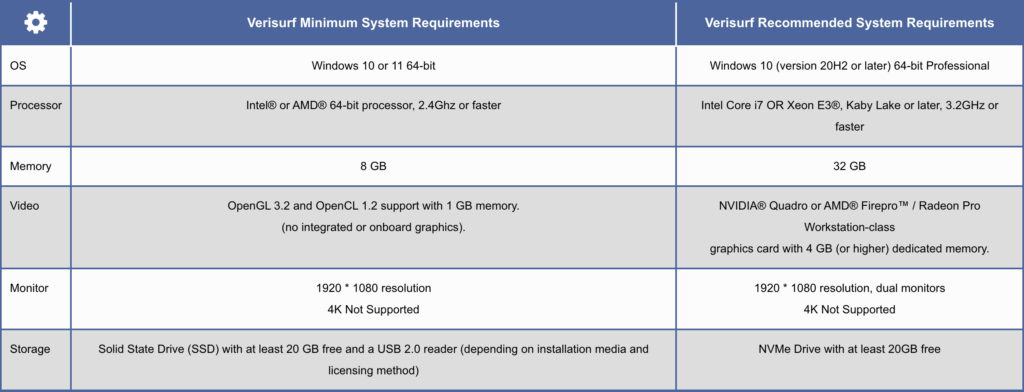

VERISURF SYSTEM REQUIREMENTS